Tip of the Week Archive

Temperature Differentials for Infrared Building Inspections – Part 1

Sponsored by:

Tip written by: Infraspection Institute

A common question among thermographers is, “How much temperature differential is needed to obtain good data?” In this two-part Tip, we discuss required temperature differentials for infrared inspections of buildings.

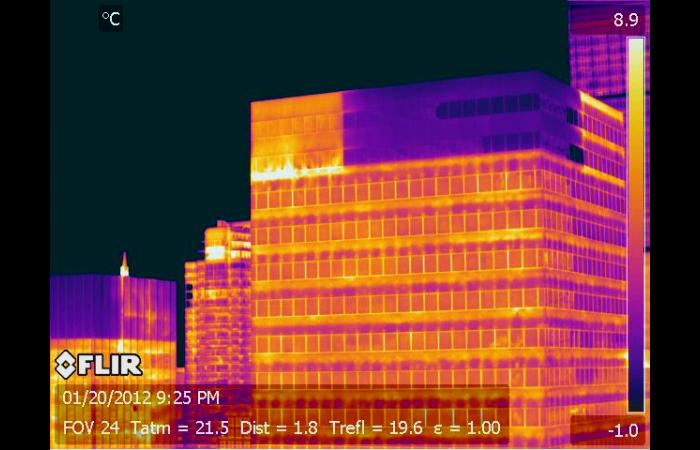

Proper conduct of any infrared inspection requires that a detectable temperature differential or Delta T is associated with the sought-after defect at the time of inspection. For infrared inspections of buildings and their subsystems, the appropriate time for an infrared inspection will depend upon, but not be limited to: the type of condition or defect, time of day, local atmospheric conditions, and imaging vantage point.

For building energy loss inspections, published standards require an inside/outside temperature differential of 10 C or 18 F degrees for at least 3 hours prior to the inspection. Such a differential will help to ensure that there is adequate heat flow through structural components necessary for an accurate inspection. While it is possible to conduct energy loss inspections with a lesser inside/outside temperature differential, the likelihood of missing defects increases with a decrease in Delta T.

IR inspections to detect building energy loss may be conducted from either the interior or exterior of a building; however, imaging from the interior is often more comprehensive and useful than macro shots taken exclusively from the exterior. Regardless of vantage point, one must make certain to account for the effects of solar loading, especially when imaging during daytime hours. Thermal patterns associated with missing or damaged insulation may appear warm or cool depending upon vantage point and site conditions.

In addition to the above, detecting latent moisture within or evaporating from building materials assumes a relatively high target emittance. Low emittance surfaces associated with metal building facades or roofs coated with aluminum paint may not lend themselves to an accurate infrared inspection.

Lastly, all infrared data should be verified by independent means, as appropriate. This testing may include visual and/or invasive moisture meter readings.

Infrared inspection of buildings is one of the many topics covered in the Infraspection Institute Level I Certified Infrared Thermographer® training course. For more information or to register for a course, visit Infraspection Institute or call us at 609-239-4788.

Advertisement