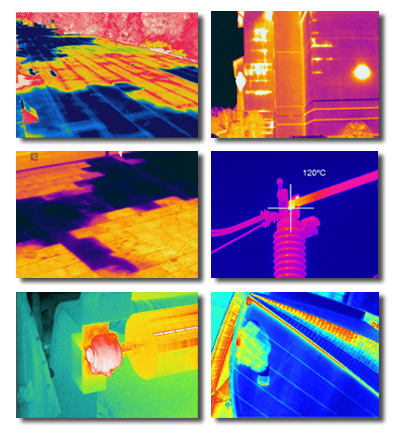

Your Online Resource For Infrared Thermography

IRINFO.ORG is a content-based web resource and online community dedicated to professionally promoting infrared thermography and related PPM, PdM and NDT technologies. Through our Articles and Tips, we offer timely, accurate information that is updated several times each week. Our comprehensive directories of IR equipment manufacturers and infrared thermographers list resources unmatched anywhere in the world. IRINFO.ORG is owned by professional infrared thermographers with decades of real-world experience in all facets of IR thermography and noncontact temperature measurement. We invite you to bookmark our site and visit often.

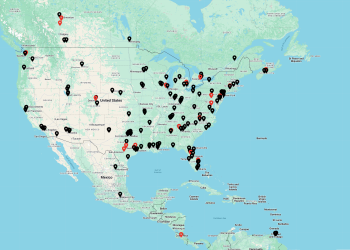

Find a Thermographer

Free Service!

Article of the Month

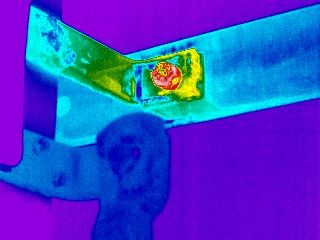

Stationary Battery String Testing Using Infrared Thermography

News

IR/INFO 2026 Sets New Record!

IIBEC Approves Infraspection Drone Course for Continuing Education Hours

Around The Globe

Featured Image

Subscribe to Our RSS Feeds

Website owners are constantly in search of new content. An RSS feed provides a mechanism to have relevant, non-competitive content delivered to your website automatically each week.

IRINFO.ORG provides RSS feeds from our News, Tip of the Week, and Feature Article sections. Subscribing to our RSS feeds will keep your website looking fresh and can vastly improve your visibility in search engines such as Google. Best of all, subscribing is FREE and you may opt out any time.