Tip of the Week Archive

IR Thermography Detects Heat Exchanger Blockage

Sponsored by:

Preventive Maintenance pays off:

Infrared Thermography Detects Heat Exchanger Blockage

~ by NATALIA KARAPAS

for The Point

Most problems on electrical systems are preceded by a change in its thermal characteristics and temperature, whether hotter or cooler. A trained and experienced thermographer is able to identify and analyze those anomalies prior to costly failures occurring.

Most problems on electrical systems are preceded by a change in its thermal characteristics and temperature, whether hotter or cooler. A trained and experienced thermographer is able to identify and analyze those anomalies prior to costly failures occurring.

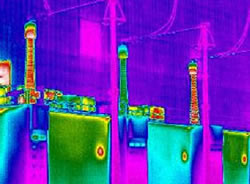

Thermography is one of the tools used by the Bruce Power Predictive Maintenance group which was created last year. Four thermographers at Bruce B and two at Bruce A started to perform thermography inspections of electrical equipment. Baseline inspections have been completed to this point on the most critical equipment. An example of a recent successful deployment of thermography is detailed here. At Bruce A, Len Bridge and Bob Forrest performed a thermography inspection of the Unit 4 main output transformer. Elevated bushing temperatures revealed an imminent problem. Inspection results successfully confirmed that the cooler was plugged due to rust buildup. The pictures describe the story.

At Bruce A, Len Bridge and Bob Forrest performed a thermography inspection of the Unit 4 main output transformer. Elevated bushing temperatures revealed an imminent problem. Inspection results successfully confirmed that the cooler was plugged due to rust buildup. The pictures describe the story. In the infrared photograph shown at left, red phase and blue phase high voltage bushings are operating at higher temperatures than the white phase bushing. The thermography image led to the discovery of a rusty buildup (shown above) that was beginning to plug the coolers.

In the infrared photograph shown at left, red phase and blue phase high voltage bushings are operating at higher temperatures than the white phase bushing. The thermography image led to the discovery of a rusty buildup (shown above) that was beginning to plug the coolers.

Photos by Len Bridge and Bob Forrest

Advertisement