Tip of the Week Archive

IR Inspections During Motor Rebuilding

Sponsored by:

Tip written by: Infraspection Institute

Thermography can be a valuable tool for testing and monitoring in-service motors. It can also be a useful tool for detecting hidden problems within motors that are being rebuilt.

Electric motors are a vital component in most industrial facilities. In the event of catastrophic failure, facility managers often elect to rebuild large or special motors. In order to maximize the service life of a remanufactured motor, it is imperative to diagnose and correct faults during the rebuilding process since unresolved defects may shorten the life of a rebuilt motor.

For motor testing, infrared imaging may be conducted by staff thermographers employed by a motor shop or an experienced third party working at the shop. During the rebuilding process, infrared imaging may be used to diagnose problems on incoming motors and to perform quality assurance checks during the rebuilding process.

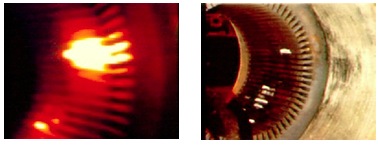

Upon arrival at the repair facility, a motor is disassembled and the rotor and stator are stripped of their coils. A high current test set is then used to excite the subject components. During excitation a thermal imager is utilized to identify thermal anomalies that are the result of short circuits and/or faulty wiring. These areas are marked so that technicians can make appropriate repairs.

due to shorted laminations.

Once the cause of thermal anomalies has been corrected, the rebuilding process will continue. Thermal imaging can be applied incrementally during the rebuilding process to help detect improper wiring or loose connections.

Infrared inspection of electric motors is one of the many topics covered in the Level I Infraspection Institute Certified Infrared Thermographer® training course. For more information or course locations and dates, call 609-239-4788 or visit us online at www.infraspection.com.

Advertisement