Tip of the Week

Watch Your Step

“Watch Your Step” is a safety slogan we’ve all seen countless times. All too frequently, thermographers suffer injuries when engrossed in an inspection or disoriented by the display monitor of an infrared imager.

Read more

News

IR/INFO 2024 a Smashing Success!

Burlington, NJ January 29, 2024 --- Infraspection Institute’s IR/INFO Conference was recently held in Orlando, FL. IR/INFO 2024 marks the 34th anniversary for the advanced training conference, technical symposium, and technology expo.

Read more

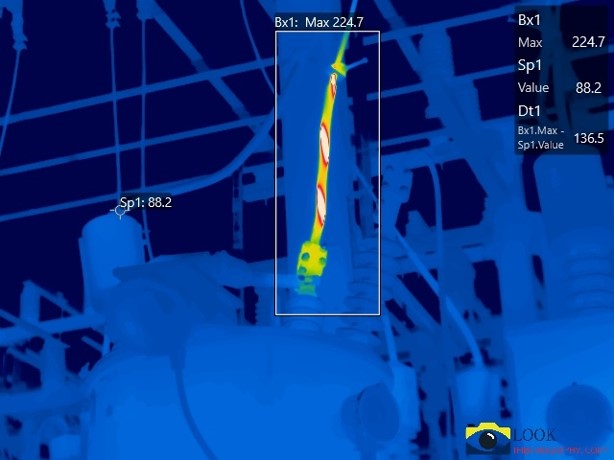

Featured Image

Thermal image shows spiral heating of a stranded conductor in an outdoor substation. Taken by Look Thermography, this thermal image was the 1st Place winner - Electrical Category in the annual Image Contest held during the IR/INFO 2023 Conference.

Read more